![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

171 Cards in this Set

- Front

- Back

- 3rd side (hint)

|

1. For applications where quiet operation and light axial load characteristics are found, the type of bearing normally used is the.

A. ball bearing. B. thrust bearing. C. sleeve bearing. D. roller bearing. |

C. sleeve bearing.

Correct. Sleeve bearings are reliable bearings when used for small motors with light loads. Further, they offer quiet operation, which is important when used in applications close to the conditioned space. |

A. ball bearing.

Incorrect. Ball bearings are relatively noisy. Further, they can handle high loads and are generally considered to be too expensive to use in light load situations. B. thrust bearing. Incorrect. Thrust bearings are used in situations where the load is trying to push or pull the shaft. D. roller bearing. Incorrect. Roller bearings are used where large axial loads are present. |

|

|

2. Sleeve bearings with the oil port lubrication system must be lubricated with the proper oil because

A. oil that is too thin will allow the shaft to run against the bearing surface B. oil that is too thick will not run into the clearance between the shaft and the bearing surface. C. the correct oil allows the motor shaft to float on a film of oil between the shaft and bearing surface. D. All of the above. |

D. All of the above.

Correct. |

|

|

|

3.Too much grease in a grease lubricated ball bearing

A. is not a problem. B. is not possible. C. causes overheating. D. reduces friction. |

C. causes overheating.

Correct. In fact, the most common cause of overheating in a ball bearing is excessive grease. |

A. is not a problem.

Incorrect. Too much grease does create a problem in a bearing, just as too little grease does. B. is not possible. Incorrect. It is possible, and a common problem, to over grease a ball bearing. D. reduces friction. Incorrect. Too much grease does not reduce friction,and should not be added to a properly greased bearing. |

|

|

4. The maximum desirable operating temperature of a ball bearing is

A. 180°F. B. 212°F C. 150°F. D. 350°F. |

A. 180°F.

Correct. A bearing hotter than 180°F is an indication of possible trouble. Infrared thermometers can be used to quickly check for hot bearings. |

B. 212°F

Incorrect. This temperature is higher than maximum desirable operating temperature. C. 150°F. Incorrect. This temperature is lower than maximum desirable operating temperature. A bearing running at 150°F is an indication of normal operation and is no cause for concern. D. 350°F. Incorrect. This is way to hot for a bearing under normal conditions and is an indication that a problem has developed. |

|

|

5. Shaft runout can be measured with

A. a dial indicator. B. a runout gage. C. a micrometer. D. Both A and B. |

D. Both A and B.

Correct. A. a dial indicator. Partially correct. A runout gage is also used for measuring runout. B. a runout gage. Partially correct. A dial indicator is also used for measuring runout. |

C. a micrometer.

Incorrect. A micrometer can be used for checking shaft diameter, but will not indicate runout. |

|

|

6. The seal in a compressor is necessary to prevent

A. refrigerant from leaking out at the rotating shaft. B. air from leaking out at the rotating shaft. C. oil from leaking out at the rotating shaft. D. Both A and C from above. |

D. Both A and C

Correct. A. refrigerant from leaking out at the rotating shaft. Correct, a function of a seal is to keep the refrigerant inside the system. C. oil from leaking out at the rotating shaft. Correct, a function of a seal is to keep the oil inside the system. |

B. air from leaking out at the rotating shaft.

Incorrect. It is the function of the seal to keep air from leaking in at the rotating shaft and contaminating the refrigerant. |

|

|

7. The mating seal surfaces on a sleeve type rotary bellows seal are

A. two polished steel surfaces. B. polished steel surfaces and neoprene. C. polished steel surfaces and a carbon ring. D. steel grooves and waxed cord. |

C. polished steel surfaces and a carbon ring.

Correct. It is the mating surfaces of the steel and carbon ring that form the seal in this type of seal. |

A. two polished steel surfaces.

Incorrect. Steel on steel makes a poor seal. B. polished steel surfaces and neoprene. Incorrect. While neoprene is used in the sleeve type rotary bellows seal, it is not the actual seal. D. steel grooves and waxed cord. Incorrect. This type of seal is sometimes used as a low pressure oil seal in applications such as automotive engines, but not in the sleeve type rotary bellows seal. |

|

|

8. A fan with a 14-inch sheave is connected by belts to a motor. Calculate the fan speed if the motor is operating at 1725 rpm and is fitted with a 5-inch sheave.

A. 4830 rpm B. 483 rpm C. 6161 rpm D. 616 rpm |

D. 616 rpm

Correct. |

A. 4830 rpm

and B. 483 rpm C. 6161 rpm Incorrect. |

|

|

9. With belt driven equipment, alignment of the motor and driven equipment pulleys

A. is not critical, since the belts are flexible. B. is accomplished using a string or straight edge. C. is accomplished when the belts are parallel to one another. D. is accomplished using a dial indicator. |

B. is accomplished using a string or straight edge.

Correct. A straight edge or string can be used to run from one pulley to the other. Alignment is complete when the string or straight edge touches both pulleys in two places at once. |

A. is not critical, since the belts are flexible.

Incorrect. Misaligned pulleys will cause excessive wear on belts, pulleys and bearings. D. is accomplished using a dial indicator. Incorrect. A dial indicator will not show misalignment between two pulleys. C. is accomplished when the belts are parallel to one another. Incorrect. The belts will always be parallel to one another, even when the pulleys are not aligned. |

|

|

10. To correct for soft foot

A. replace soft material with a material of sufficient hardness. B. shim under the high foot with shim stock equal to a reading on the indicator. C. replace the resilient material in the coupling. D. replace vibration isolators with isolators properly rated for the pump. |

B. shim under the high foot with shim stock equal to a reading on the indicator.

Correct. The indicator is set up to read any movement as a mounting bolt is loosened. If loosening the bolt allows a foot to raise up, there is a soft foot condition, and shims must be added below the foot before the bolt is retightened. |

A. replace soft material with a material of sufficient hardness.

Incorrect. Soft foot is a condition in which one of the feet of a piece of machinery does not set flat on the base. C. replace the resilient material in the coupling. Incorrect. Soft foot is a condition in which one of the feet of a piece of machinery does not set flat on the base and does not apply to couplings. D. replace vibration isolators with isolators properly rated for the pump. Incorrect. Soft foot is a condition in which one of the feet of a piece of machinery does not set flat on the base and distorts the equipment when bolted down. There are no vibration isolators located between the equipment and the base. |

|

|

11. The two planes of alignment that must be considered when aligning a flexible coupling are

A. axial and parallel. B. parallel and perpendicular. C. horizontal and vertical. D. parallel and angular. |

D. parallel and angular.

Correct. Shafts must be aligned so that the centerlines meet each other exactly in the center (parallel to one another, or axially), and they must be aligned so that they have no angular difference between them (also called radial alignment). |

A. axial and parallel.

Incorrect. Axial and parallel mean the same thing in reference to a shaft. However, the shafts must be aligned parallel to one another, which is the same as saying that they must be aligned axially. This means that their centerlines must line up. B. parallel and perpendicular. Incorrect. While it is true enough that the shafts must be aligned parallel to one another, they cannot be perpendicular to one another. C. horizontal and vertical. Incorrect. |

|

|

12. Electrical pressure is measured in

A. amps B. ohms. C. watts. D. volts. |

D. volts.

Correct. |

A. amps

Incorrect. Amperage is a measure of flow, not pressure. B. ohms. Incorrect. Ohms are a measure of resistance, not pressure. C. watts. Incorrect. Watts is a measure of power, not pressure. |

|

|

13. results from the movement of tiny negatively charged particles called

A. protons. B. electrons. C. neutrons. D. ions. |

B. electrons.

Correct. |

A. protons.

Incorrect. Protons, while part of the atom, are positively charged and exist in the necleus but do not make electrical current. C. neutrons. Incorrect. Neutrons, while part of the atom, carry a neutral charge and exist in the necleus but do not make electrical current. D. ions. Incorrect. Ions are atoms that carry a charge, either negative or positive. When an electron leaves an atom, that atom becomes a positively charged ion since it now has positivley charged protons that outnumber the negaively charged electrons. It is the movement of the free electron that causes electricity. |

|

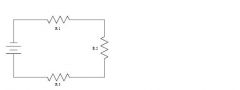

14. Calculate the voltage in the circuit when the total amperage is 10 amps and the resistors have

values as follows: R1=10 ohms, R2=15 ohms, R3=20 ohms. A. 0.45 volts. B. 4.5 volts. C. 450 volts. D. 0.222 volts. |

C. 450 volts.

Correct. Rt = R1 + R2 + R3 Use Ohm’s Law to calculate the value for voltage in this series circuit. Remember that resistance is added in a series circuit. |

A. 0.45 volts.

B. 4.5 volts. D. 0.222 volts. Incorrect. Use Ohm’s Law to calculate the value for voltage in this series circuit. Remember that resistance is added in a series circuit. Rt = R1 + R2 + R3 |

|

15. Calculate the value for R3 when the value for R1=150 ohms, R2=500 ohms, the voltage is 120 volts and the amperage is 0.12 amps.

A. 1000 ohms. B. 100 ohms. C. 10 ohms. D. 350 ohms. |

D. 350 ohms.

Correct. Use Ohm’s Law to calculate the value for resistance in this series circuit. Remember that Ohm’s Law will give total resistance. In this case, the value for only one resister is needed. Rt = 150 + 500 + R3 Volts + Amps X Ohms (Rt) or Ohms (Rt) = Volts Divided By Amps 1000 (Rt) = 120 Divided by 0.12 R3 = Rt – (R1 + R2) |

A. 1000 ohms.

B. 100 ohms. C. 10 ohms. Use Ohm’s Law to calculate the value for resistance in this series circuit. Remember that Ohm’s Law will give total resistance. In this case, the value for only one resister is needed. Rt = 150 + 500 + R3 Volts + Amps X Ohms (Rt) or Ohms (Rt) = Volts Divided By Amps 1000 (Rt) = 120 Divided by 0.12 R3 = Rt – (R1 + R2) |

|

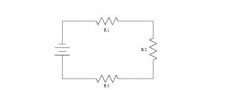

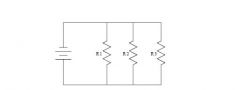

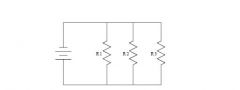

16. Calculate the voltage in the circuit when the total amperage is 20.4 amps and the resistors have values as follows: R1=10 ohms, R2=50 ohms, R3=20 ohms.

A. 120 volts. B. 240 volts. C. 1632 volts. D. 3.92 volts. |

A. 120 volts.

Correct. Use Ohm’s Law to calculate the value for voltage in this parallel circuit. Remember that in parallel circuits, current is additive, resistance is not. |

B. 240 volts.

C. 1632 volts. D. 3.92 volts. Incorrect. Use Ohm’s Law to calculate the value for voltage in this parallel circuit. Remember that in parallel circuits, current is additive, resistance is not. |

|

17. What is the maximum safe amperage draw of the secondary winding of a 60 VA transformer output of 12 volts?

A. 0.2 amps. B. 5 amps. C. 720 amps. D. 7.2 amps. |

B. 5 amps.

Correct Divide VA by volts to obtain the correct answer. |

A. 0.2 amps.

C. 720 amps. D. 7.2 amps. Incorrect. Divide VA by volts to obtain the correct answer. |

|

|

18. The best way to determine the voltage requirements for an electrical component is to

A. read line voltage with a digital multimeter. B. read the name plate data. C. check with the utility company. D. determine the capacity of the service panel. |

B. read the name plate data.

Correct. |

A. read line voltage with a digital multimeter.

Incorrect. Line voltage will merely show what is connected to the component. It may or may not be the correct voltage. C. check with the utility company. Incorrect. The utility company will not know what is required for a specific component without reading the name plate or consulting with the manufacturer. D. determine the capacity of the service panel. Incorrect. The capacity of the service panel is typically several times greater than the needs of an electrical component. Further, while servied panels must have the required voltage, they are rated in amperage at a certain voltage. |

|

|

19. Fuses can be checked

A. with an ohm meter. B. with a volt meter. C. with an ammeter. D. Both A and B from above. |

D. Both A and B.

Correct. This is the best answer. A. with an ohm meter. Partially correct, although not the best answer. On a dead circuit or with the fuse removed from the circuit, an ohm meter will read 0 ohms across the fuse if the fuse is good. If the fuse is bad, the reading will be ∞ ohms. B. with a volt meter. Partially correct, although not the best answer. On a live circuit, a volt meter will register no reading across a good fuse. A bad fuse will return a reading of line voltage. |

C. with an ammeter.

Incorrect. An ammeter can only indicate how much current is flowing. If the circuit is live, the ammeter will show a reading if the fuse and all other components are operating correctly. However, if a component has failed and caused an interruption in current flow, the ammeter will not read and may cause the technican to think the fuss is bad. There is not a way to isolate the fuse for testing using only an ammeter. |

|

|

20. Which of the following devices may be wired into the starting circuit of a single phase motor to improve the starting torque?

A. winding thermostat. B. start capacitor. C. another winding. D. Both B and C. |

D. Both B and C.

Correct. This is the best answer, as both starting windings and start capacitors improved starting torque, although start capacitors provide more torque than start windings. B. start capacitor. Partially correct, although not the best answer. Start capacitors do improve starting torque. C. another winding. Partially correct, although not the best answer. Start windings are used in all single phase induction motors to get them started. However, start windings provide only a small amount of torque. When used without start capacitors, split-phase motors are limited to low-starting torque applications. |

A. winding thermostat.

Incorrect. |

|

|

21. A single phase motor with an improved power factor, reduced motor current, increased efficiency and high starting torque is the

A. capacitor start-capacitor run (CSR) motor. B. shaded pole motor. C. split phase motor. D. permanent split-capacitor motor. |

A. capacitor start-capacitor run (CSR) motor.

Correct. Because of the run and start capacitor, this motor offers the advantages listed above. The down side is additional cost. |

B. shaded pole motor.

Incorrect. This motor has very low starting torque and is limited to small low-torque applications such as small fans and pumps. C. split phase motor. Incorrect. This motor has low to medium starting torque and is limited to fractional horsepower applications. No capacitors are used in the motor for either starting or running. D. permanent split-capacitor motor. Incorrect. This motor has high efficiency but low starting torque. It features a run capacitor wired in series with the start winding and in parallel with the run winding. |

|

|

22. In a CSR motor with a 10 microfarad run capacitor and a 110 microfarad start capacitor, the total capacitance will be

A. 60 microfarads. B. 120 microfarads. C. 9.17 microfarads. D. 100 microfarads. |

B. 120 microfarads.

Correct. The capacitance of capacitors, when wired in parallel as in a CSR motor, are added together the same as resistors in a series circuit. |

A. 60 microfarads.

C. 9.17 microfarads. D. 100 microfarads. Incorrect. The capacitance of capacitors, when wired in parallel as in a CSR motor, are added together the same as resistors in a series circuit. |

|

|

23. The instrument used for finding humidity levels in the atmosphere is the

A. sling psychrometer B. micron gage. C. manometer. D. infrared thermometer. |

A. sling psychrometer

Correct. This instrument provides both wet bulb and dry bulb readings that can be used with the Psychrometric Chart to determine the properties of the air just sampled. |

B. micron gage.

Incorrect. This device is used to measure deep vacuums in refrigeration systems. C. manometer. Incorrect. This instrument is used for determining pressure. D. infrared thermometer. Incorrect. This instrument is used for determining temperature. |

|

|

24. For reading the lowest vacuum levels, the best instrument to use is

A. a gage manifold set. B. a manometer. C. electronic vacuum gage. D. wet-bulb type vacuum indicator. |

C. electronic vacuum gage.

Correct. Electronic vacuum gages are sufficiently accuract to measure pressureses down below 2000 microns. |

A. a gage manifold set.

Incorrect. The compound gage on the gage manifold can only read to an accurace of 1 in.Hg. Compressor manufactures are calling for evacuation levels down to 500 microns or less. Since there 25.4 millimeters in an inch, and 1000 microns in a millimeter, 1 in.Hg. becomes 25,400 microns. In other words, each inch of vacuum on the compound gage is the same as 25,400 microns! 500 microns is approximatly 1/50 of 25,400, so a technician trying to read 500 microns on the compound gage would have to divide the increment between 29 and 30 on the gage into 50 parts and read when the needle reached the last mark. B. a manometer. Incorrect. This gage reads in mm.Hg. so it is 25.4 times more accurate than the compound gage, which reads in in.Hg. However, compressor manufactures are calling for evacuation levels down to 500 microns or less. Since there are 1,000 microns in a millimter, a reading of 500 microns is equal to ½ millimeter. It is not possible to read this accurately on a manometer. D. wet-bulb type vacuum indicator. Incorrect. While this instrument can be very accurate under perfect conditions, it is not reliable enough for the technician to count on it as dependable. |

|

|

25. A hermetic motor should never be energized or tested with a megger when in a deep vacuum because

A. electric arcs can contaminate refrigerant in the system. B. the motor could draw too much amperage. C. the vacuum pump could be damaged. D. the dielectric strength of the motor’s insulation would be greatly reduced. |

D. the dielectric strength of the motor’s insulation would be greatly reduced.

Correct. Deep vacuums have the effect of greatly reducing the dielectric strength of hermetic compressor motors insulation. Therefore, a hermetic compressor motor should never be energized, no matter how briefly, while it is in a deep vacuum. This would include performing a megger test of the motor’s insulation while it is in a deep vacuum. |

A. electric arcs can contaminate refrigerant in the system.

Incorrect. During a deep vacuum, the refrigerant is no longer in the system. B. the motor could draw too much amperage. Incorrect. Very little amperage would be drawn due to the lack of load on the motor. C. the vacuum pump could be damaged. Incorrect. The system compressor would have no effect on the vacuum pump. |

|

|

26. Which of the following reduced voltage starters uses a switching arrangement to connect the windings of three-phase motors in different configurations during startup and normal operation?

A. Autotransformer starters. B. Start-run starters. C. Star-wye starters. D. Star-delta starters. |

D. Star-delta starters.

Correct. Star-delta starters connect the motor in a star (or wye) arrangement during startup, which reduces starting voltage to approximately 58% of line voltage. This limits starting current to about one third that of what it would be if the windings were connected in delta at startup. Once the motor has accelerated, the wiring configuration is switched to delta, and the motor continues to run under full voltage. |

A. Autotransformer starters.

Incorrect. The autotransformer uses a transformer to reduce the voltage during startup. Once the motor has accelerated, the transformer is taken out of the circuit and the motor continues to run on full voltage. B. Start-run starters. Incorrect. There is no such thing as a start-run starter. C. Star-wye starters. Incorrect. Star and wye mean the same thing when referreing to three-phase configurations. |

|

|

27. According to NEC (National Electrical Code), a general-use switch may be used as the controller for a stationary motor rated at two horsepower or less and at 300 volts or less if it is rated at not less than

A. the full-load motor current. B. twice the full-load motor current. C. three times the full-load motor current. D. five times the full-load motor current. |

B. twice the full-load motor current.

Correct. |

A. the full-load motor current.

Incorrect. Motors draw more current during startup than at full-load, so switch damage or failure could occur during the startup cycle if the switch is reated only for full-load. C. three times the full-load motor current. Incorrect. While it is true that motors can draw several times more current during startup than during full-load, NEMA does not require the switch rating to be three times the full-load motor current. D. five times the full-load motor current. Incorrect. While it is true that motors can draw several times more current during startup than during full-load, NEMA does not require the switch rating to be five times the full-load motor current. |

|

|

28. Two types of thermal overload relays in common use today are

A. the bimetal relay and the magnetic relay. B. the melting alloy relay and the Mercury bulb. C. the bimetal relay and the melting alloy relay. D. the bimetal relay and the trimetal relay. |

C. the bimetal relay and the melting alloy relay.

Correct. |

A. the bimetal relay and the magnetic relay.

Incorrect. The magnetic relay is another type of overload that uses the principle of magnetism instead of heat to protect the motor. B. the melting alloy relay and the Mercury bulb. Incorrect. Mecury bulbs are commonly used as switches in thermostats,. but are not used for overload protection. D. the bimetal relay and the trimetal relay. Incorrect. There is no such thing as a trimetal relay. |

|

|

29. A rather common indication of a defective starting relay in a single phase motor

A. is for the motor to hum but not start. B. is for the motor to start, run normally, then shut down after several minutes. C. is the motor to start but not come up to speed. D. the motor starts but runs in the wrong direction. |

A. is for the motor to hum but not start.

Correct. |

B. is for the motor to start, run normally, then shut down after several minutes.

Incorrect. The starting relay has done its job in this situation. Other problems could be causing the motor to stop, such as a defective overload relay or an overloaded motor. C. is the motor to start but not come up to speed. Incorrect. The starting relay has energized the motor but something else is preventing it from coming up to speed such as a bad start capacitor. D. the motor starts but runs in the wrong direction. Incorrect. The motor has been wired incorrectly. |

|

|

30. The level of voltage caused by back electromotive force that opens the contacts on a potential relay in order to take the start capacitor out of the circuit is called

A. lift voltage. B. open voltage. C. run voltage. D. Pick-up voltage. |

D. Pick-up voltage.

Correct. |

A. lift voltage.

Incorrect. Lift voltage is a made up term. B. open voltage. Incorrect. Open voltage is a made up term. C. run voltage. Incorrect. Run voltage is a made up term. Refer to the UA text or consult with an instructor or technician to find the correct answer. |

|

|

31. A type of current relay that uses a bimetal strip to open contacts in both the starting and running

contacts is called A. hot-wire relay. B. bimetal relay. C. start/run relay. D. “Gallert” relay. |

A. hot-wire relay.

Correct. |

B. bimetal relay.

Incorrect. Although a bimetal strip is used to sense heat, the relay is not called a bimetal relay. C. start/run relay. Incorrect. Although the relay takes the starting winding out of the circuit once the motor comes up to speed and acts as an overload device once the motor is running, it is not called a start/run relay. D. “Gallert” relay. Incorrect. “Gallert” is a name chosed radomly from a phone book and has nothing to do with starting relays. |

|

|

32. A pneumatic timing relay operates by

A. receiving air from the pneumatic control system. B. filling a bellows with air. C. sensing air from a motor's cooling fan. D. changing air pressure after a set amount of time. |

B. filling a bellows with air.

Correct. When energized, a bellows fills with air, which takes time. The time can be adjusted by a needle valve, which regulates the rate at which the bellows fills. When fully expanded, the bellows operates a snap-action switch. |

A. receiving air from the pneumatic control system.

Incorrect. the pneumatic timing relay is not connected to a pneumatic control system. C. sensing air from a motor's cooling fan. Incorrect. The pneumatic timing relay can be mounted remotely from the motor and is not affected by air flow. D. changing air pressure after a set amount of time. Incorrect. The pneumatic timing relay is not connected to a pressure device and does not alter the pressure of any component. |

|

|

33. The combination safety limit and fan control on a residential furnace turns the fan on and off by sensing the furnace air temperature. If the furnace temperature rises too high, the safety limit deenergizes the

A. fan and main gas valve. B. fan. C. gas valve. D. igniter. |

C. gas valve.

Correct. The gas valve is shut off while the fan is allowed to continue running in order to cool the furnace. |

A. fan and main gas valve.

Incorrect. The fan is allowed to continue running in order to cool the furnace. B. fan. Incorrect. The fan is allowed to continue running in order to cool the furnace. D. igniter. Incorrect. On many furnaces, the ignitor is de-energized as soon as the main burner ignites. If the furnace has gotten too hot, the main burner would already be ignited and the ingnitor would likely already be off. Further, it is the main burner, not the ignitor (or pilot) that is the source of heat causing the overheating. |

|

|

34. Some codes require a manual reset device on a safety limit

A. so that the cause of the safety shutdown can be investigated prior to re-start. B. so that the equipment will not short-cycle. C. so that more technicians are needed, which helps the economy. D. because automatic reset is more costly. |

A. so that the cause of the safety shutdown can be investigated prior to re-start.

Correct. |

B. so that the equipment will not short-cycle.

Incorrect. While it is true that a manual reset requires a person to reset the safety and would help to prevent short-cycle operation, the code is written so that the root cause of the safety shutdown can be identified. C. so that more technicians are needed, which helps the economy. Incorrect. Code officials do not consider the impact on the economy when writing code. D. because automatic reset is more costly. Incorrect. Code officials are concerned with safety and not cost. |

|

|

35. In order to protect a load, safety limit devices are most often wired

A. in parallel. B. in series. C. upstream. D. downstream. |

B. in series.

Correct. Series wiring de-energizes the load when any one of several safeties trips. |

A. in parallel.

Incorrect. Parallel wiring would allow the load to be energized even if one safety tripped. C. upstream. Incorrect. It doesn’t matter if the safety limit is “upstream” or “downstream” of the load. What does matter is if it is in series or parallel. D. downstream. Incorrect. It doesn’t matter if the safety limit is “upstream” or “downstream” of the load. What does matter is if it is in series or parallel. |

|

|

36. A flow switch safety control is used to

A. control the amount of flow of a fluid (liquid or gas). B. turn on a pump or fan. C. divert fluid flow during unsafe conditions. D. prove that flow is occurring. |

D. prove that flow is occurring.

Correct. These switches prove that flow is occuring, such as in water piping to hot water boilers to verify that the pumps are operating and water is flowing before the main gas valve is opened, or to ensure that water is flowing through chiller barrels before energizing the compressor. |

A. control the amount of flow of a fluid (liquid or gas).

Incorrect. The purpose of this switch is simply to prove that flow is occuring. B. turn on a pump or fan. Incorrect. The purpose of this switch is to prove that flow is occuring. The fan or pump would already have to be energized in order for the switch to sense flow. C. divert fluid flow during unsafe conditions. Incorrect. The purpose of this switch is simply to prove that flow is occuring. |

|

|

37. What is a disadvantage of the mercury bulb switch?

A. They are unreliable. B. They must be level. C. They tend to burn contacts. D. They tend to “chatter”, which cycles the load on and off. |

B. They must be level.

Correct. In order to operate correctly, the thermostat must be mounted absolutely level. |

A. They are unreliable.

Incorrect. Mercury bulb sensors are very reliable. C. They tend to burn contacts. Incorrect. Mercury bulb sensors last for years without every burning contact. D. They tend to “chatter”, which cycles the load on and off. Incorrect. Because the mass of mecury flows from one end of the bulb to the other, the contact is made very rapidly. The switch cannot “chatter” because of the inertia contained in the mass of mercury. |

|

|

38. A thermostat is properly calibrated when

A. set point and control point are equal. B. room temperature is comfortable. C. there is no deadband. D. control point and thermostat reading agree. |

D. control point and thermostat reading agree.

Correct. |

A. set point and control point are equal.

Incorrect. Set point refers to the manual setting of the thermostat while control point refers to the actual temperature of the space. The difference between the two is known as offset. When set point and control point are equal, offset is zeor and the thermostat is said to be “satisfied”. B. room temperature is comfortable. Incorrect. Room temperature comfort is subjective and varies from person to person. C. there is no deadband. Incorrect. In many cases, deadband is a desirable condition and occurs whether the thermostat is calibrated or not. |

|

|

39. With a change in temperature, a thermistor will change

A. resistance. B. voltage. C. current. D. impedance. |

A. resistance.

Correct. |

B. voltage.

C. current. D. impedance. Incorrect. Thermistors are variable resistors that change with temperature. |

|

|

40. One type of pressure sensing device uses a flattened metal tube, which is bent into a part-circle

with one end fixed in place and connected to a system to be measured. The other end of the tube is closed and free to move. An increase in pressure tends to straighten the tube. The movement of the free end of the tube is connected to a dial that reads pressure. This type of gage is called a A. Whiskey tube. B. bimetal tube. C. Bourdon tube. D. flat-tube gage. |

C. Bourdon tube.

Correct. |

A. Whiskey tube.

Incorrect. B. bimetal tube. Incorrect. Bimetal is used to sense temperature, not pressure. D. flat-tube gage. Incorrect. |

|

|

41. A pressure sensing device that relies on a fluid, such as oil, to provide a frictionless seal is the

A. Whiskey tube B. oil pressure gage. C. inverted bell. D. inverted bucket. |

C. inverted bell.

Correct. This device is suitable on only very low pressure, such as static pressure in an Air duct, where pressures usually do not exceed several inches of water. |

A. Whiskey tube

Incorrect. The Whiskey tube is not a pressure sensing device. B. oil pressure gage. Incorrect. While oil is commonly used to provide the fluid and frictionless seal, oil pressure is normally not sensed with this type of device. D. inverted bucket. Incorrect. The inverted bucket is used in steam trap design, but is not used for pressure sensing. |

|

|

42. An advantage of a diaphragm is that it can produce a large force when acted upon by only a small pressure. Calculate the total force exerted by an 8" diaphragm with a pressure of 1.8 psig applied to the diaphragm.

A. 362 pounds. B. 90.5 pounds. C. 56.54 pounds. D. 14.4. pounds. |

B. 90.5 pounds.

|

A. 362 pounds.

C. 56.54 pounds. D. 14.4. pounds. Incorrect. Area of a circle is A =π r squared . Don't forget to divide the diameter by two before calculating the area of the circle. |

|

|

43. The photo cell in an infrared sensor is made of

A. lead sulfide. B. cadmium sulfide. C. a sealed gas-filled chamber. D. zinc sulfide. |

A. lead sulfide.

Correct. Lead sulfide is a semiconductor having the property of decreasing in electrical resistance when exposed to radiation of certain wave lengths. |

B. cadmium sulfide.

Incorrect. Cadmium sulfide is used as a photocell in a visible light detector. C. a sealed gas-filled chamber. Incorrect. Ultraviolet flame detectors use a sealed gas-filled chamber containing two Electrodes. When the gas is exposed to ultraviolet light, the gas becomes conductive and Current pulses from one electrode to the other, thus sensing the flame. D. zinc sulfide. Incorrect. |

|

|

44. Aiming of infrared sensors is critical. Why must they be aimed directly at the flame?

A. Since they see light, they can be fooled by the bright area surrounding the flame. B. Since they see heat, they can be fooled by the hot air surrounding the flame. C. Since they see heat, they can be fooled by hot refractory. D. Since they see heat, their sensitivity can be reduced by hot refractory. |

D. Since they see heat, their sensitivity can be reduced by hot refractory.

Correct. The steady glow of a hot refractory will cause some decrease in resistance of the photocell material, which reduces the sensitivity of the system. For this reason, the photocell should be installed so that it does not directly "see" the refractory. |

A. Since they see light, they can be fooled by the bright area surrounding the flame.

Incorrect. Infreared sensors do not see visible light, so they are not fooled by light. B. Since they see heat, they can be fooled by the hot air surrounding the flame. Incorrect. Infrared sensors are not fooled by hot combustion products. C. Since they see heat, they can be fooled by hot refractory. Incorrect. Infrared sensors can be fooled by hot refractory, so the sensing circuits are built to eliminte this problem. Flames flicker and the circuit responds to the rapidly changing resistance caused by the flicker. The steady glow of a hot refractory does not flicker, so the circuit does not respond. |

|

|

45. A type of two-position control that provides for "intermediate" positions as well as the "all-on" and "all-off" positions is the

A. timed two-position control. B. deviation control. C. percentage control. D. floating control. |

D. floating control.

Correct. |

A. timed two-position control.

Incorrect. Timed two-position control refers the the practice of using heating and/or cooling anticipators to provide smaller amounts of heating or cooling at more frequent intervals to prevent wide temperature differentials. B. deviation control. Incorrect. Deviation is a term for the difference between the diesired value and the actual value of the controlled variable. C. percentage control. Incorrect. The concept of "percentage" control does exist, but is called proportional control and allows a controlled device to stop at any point along its throttling range (also called proportional band). |

|

|

46. While proportional control action has the disadvantage of control point shift but has no time-lag

factor, floating action has the disadvantage of time lag influence but has no control point shift. What control action combines the advantages of both? A. Proportional integral. B. Proportional with feedback. C. Floating proportional control. D. single-speed floating action. |

A. Proportional integral.

Correct. PI control has no time lag factor and maintains a single control point. |

B. Proportional with feedback.

Incorrect. All proportional control includes feedback. To say proportional with feedback is to be redundant. C. Floating proportional control. Incorrect. Proportional is considered to be a type of floating control in and of itself. D. single-speed floating action. Incorrect. Single-speed floating action is considered to be a type of floating control in and of itself and carries with it the disadvantages of floating control. |

|

|

47. A flame sensing strategy that takes advantage of the fact that hot gasses in a flame become ionized and conduct electricity is called a

A. cad cell. B. thermocouple. C. flame rod. D. ion sensor. |

C. flame rod.

Correct. Flame rods are designed so that current is conducted in the flame is much stronger in one direction (half cycle) than in the other, which produces a rectified signal. |

A. cad cell.

Incorrect. Cad cells "see" flame if it is colored yellow, as is fuel oil flame. Cad cells do not work for the blue flame of natural gas systems. B. thermocouple. Incorrect. Thermocouples produce small voltage (about 30 millivolts DC) when heated in a flame. They use the principle that two dissimilar metals that are fused together at one end to form a "hot" junction, and open at the opposite end to form a "cold" junction, will generate electrical voltage when heating. D. ion sensor. Incorrect. |

|

|

48. Checking amperage on a system during general maintenance

A. is a waste of time and should be avoided. B. should only be done if a problem is suspected. C. can indicate a problem with the system. D. should only be done with the power off for safety reasons. |

C. can indicate a problem with the system.

Correct. Amperage readings that are too high or too low can be an indication of electrical, mechanical or refrigerant charge problems with the system. |

A. is a waste of time and should be avoided.

Incorrect. Amperage readings can indicate problems with a system that appears to be operating normally. B. should only be done if a problem is suspected. Incorrect. Taking and recording amperage readings during maintenance periods provides a history of the system. If an amperage reading falls out of the normal range, a problem may be developing that is not otherwise apparent. D. should only be done with the power off for safety reasons. Incorrect. The system must be running in order to read amperage. |

|

|

49. When changing or adding oil to a compressor

A. it is best to buy the smallest possible containers and use the entire contents at once. B. avoid pouring the oil from a container into the compressor. C. use an oil charging pump. D. all of the above. |

D. all of the above.

Correct. A. it is best to buy the smallest possible containers and use the entire contents at once. Partially correct. Purchasing large containers of oil may be cheaper, but will likely lead to contamination of the oil, which could lead to system problems. A special oil charging pump can help eliminate this problem if it is put on a can of oil and left there until all of the oil has been pumped out. B. avoid pouring the oil from a container into the compressor. Partially correct. Pouring the oil through the atmosphere will admit water and air to the system. C. use an oil charging pump. Partially correct. When possible, the use of an oil charging pump will eliminate the introduction of water, air and other contaminants into the compressor. These pumps are fitted with a filter dryer that keeps the oil free of dirt and moisture. |

|

|

|

50. As the evaporating temperature of any vapor compression system is lowered,

A. compressor suction vapor density increases. B. the volume of the suction vapor decreases. C. compressor capacity is lowered. D. flash gas in the liquid line is likely to occur. |

C. compressor capacity is lowered.

Correct. |

A. compressor suction vapor density increases.

Incorrect. At lower evaporating temperature, there is a corresponding lower pressure, which decreases vapor density. B. the volume of the suction vapor decreases. Incorrect. At lower evaporating temperature, there is a corresponding lower pressure, which increases vapor volume. D. flash gas in the liquid line is likely to occur. Incorrect. The evaporator is on the low side of the system while the liquid line is on the high side of the system. As evaporator temperature lowers, evaporator pressure lowers, decreasing the capacity of the compressor and the amount of refrigerant that is flowing. Flash gas in the liquid line is often caused by friction due to excessive velocity. When compressor capacity is reduced, less refrigerant flows, meaning lower velocities in the liquid line, and less likelihood of flash gas. |

|

|

51. As a "rule of thumb", for every 12,000 btuh of cooling capacity in an open compressor air conditioning system, the heat rejection is roughly

A. 12,000 btuh, or 1.0 times the net refrigeration effect. B. 9,000 btuh, or 0.75 times the net refrigeration effect. C. 15,000 btuh, or 1.25 times the net refrigeration effect. D. none of the above |

C. 15,000 btuh, or 1.25 times the net refrigeration effect.

Correct. Like any rule of thumb, this number can vary. However, as a basis for estimation, it has long been considered that the heat rejection from an air conditioning system is about 15,000 Btuh for every 12,000 Btuh of coling capacity. This assumes open-type compressors, where the refrigerant suction vapor does not receive any heat from the compressor moter as it does in nermetic motor-compressors. |

A. 12,000 btuh, or 1.0 times the net refrigeration effect.

Incorrect. The heat of rejection will always be greater than the net refrigeration effect due to superheat and compressor cooling. B. 9,000 btuh, or 0.75 times the net refrigeration effect. Incorrect. The heat of rejection must be at least equal to the net refrigeration effect, and is in fact greater. D. none of the above Incorrect. |

|

|

52. The difference in temperature between condensing temperature and entering water or air

temperature is known as A. temperature split B. Subcooling C. Superheat D. temperature rise |

A. temperature split

Correct. The condensing temperature should be at least 15 or 20 degrees higher than the temperature of the entering water or air to avoid the need for an unreasonable large and costly condenser. |

B. Subcooling

Incorrect. Subcooling is the process of cooling refrigerant below condensing temperature, for a given pressure. A good discussion on subcooling can be found on page 71 of Refrigeration. Information on determining subcooling can be found in Chapter 4 of Refrigerant Controls. C. Superheat Incorrect. Superheated vapor is vapor that is above its saturation temperature. A good discussion on superheated vapor can be found on Page 29 of Refrigeration. Page 6 of Refrigerant Controls provides further information on superheat. Information on determining superheat can be found on page 43 of Refrigerant Controls. D. temperature rise Incorrect. Temperature rise is a generic term sometimes used to describe the difference in temperature between entering and leaving fluid flows conditions, i.e. the air temperature rise as it flow across a heating coil. |

|

|

53. A decrease in condensing temperature will

A. increase condensing pressure, increase suction temperature and increase system capacity. B. decrease condensing pressure, increase suction temperature and increase system capacity. C. decrease condensing pressure, decrease suction temperature and increase system capacity. D. decrease condensing pressure, decrease suction temperature and decrease system capacity. |

C. decrease condensing pressure, decrease suction temperature and increase system capacity.

Correct. A decrease in condensing temperature affects the entire system, and will cause a drop in evaporator pressure. The drops in both condensing and evaporator pressures (and temperatures) result in a higer system capacity. |

A. increase condensing pressure, increase suction temperature and increase system capacity.

Incorrect. A decrease in condensing temperature will result in a decrease in condensing pressure. As long as the refrigerant is in a state of constant quality (part vapor, part liquid), any change in temperature will result in a corrosponding change in pressure. This can be seen on a pressure-enthalpy diagram of any refrigerant. B. decrease condensing pressure, increase suction temperature and increase system capacity. Incorrect. As condensing pressure drops, so will suction pressure. D. decrease condensing pressure, decrease suction temperature and decrease system capacity. Incorrect. A decrease in condensing temperature will decrease both condensing and suction pressure and will increase system capacity. |

|

|

54. Subcooling in the condenser will

A. increase system capacity. B. decrease system capacity. C. not affect system capacity. D. increase the flash gas loss. |

A. increase system capacity.

Correct. An increase in subcooling will increase the net refrigeration effect by reducing the flash gas loss. |

B. decrease system capacity.

Incorrect. Subcooling will increase the net refrigeration effect by reducing the flash gas loss. C. not affect system capacity. Incorrect. Subcooling will increase the net refrigeration effect by reducing the flash gas loss. D. increase the flash gas loss. Incorrect. Subcooling will actually reduce the flash gas loss, and will increase net refrigeration effect in the process. |

|

|

55. Compressor capacity controlled by the cylinder unloading method

A. may result in compressor overheating B. is only used with hermetic compressors. C. does not provide energy savings. D. is only used with systems charged with ammonia. |

A. may result in compressor overheating

Correct. As fewer cylinders are used, less refrigerant is pumped resulting in less refrigerant vapor available for cooling the compressor. |

B. is only used with hermetic compressors.

Incorrect. This method is only used with reciprocating compressors. C. does not provide energy savings. Incorrect. Energy savings are provided as cylinders are unloaded, since the compressor does less work. D. is only used with systems charged with ammonia. Incorrect. This method can be used with many refrigerants. |

|

|

56. 10 in.Hg. vacuum is approximately equivalent to

A. 5 psig. B. 5 psia. C. 10 psig. D. 10 psia. |

|

A. 5 psig.

Incorrect. A perfect vacuum is approximately 30 in. Hg. vacuum and 0 psia, while atmospheric pressure is 0 in.Hg. vacuum and roughly 15 psia. Use interpolation to estimate what the pressure would be at 10 in.Hg. B. 5 psia. Incorrect. A perfect vacuum is approximately 30 in. Hg. vacuum and 0 psia, while atmospheric pressure is 0 in.Hg. vacuum and roughly 15 psia. Use interpolation to estimate what the pressure would be at 10 in.Hg. C. 10 psig. Incorrect. perfect vacuum is approximately 30 in. Hg. vacuum and 0 psia, while atmospheric pressure is 0 in.Hg. vacuum and roughly 15 psia. Use interpolation to estimate what the pressure would be at 10 in.Hg. |

|

|

57. After repairing a leak, it is permissible to pressure test a system using nitrogen with a small amount of _______ added as a trace gas.

A. helium. B. oxygen. C. CFC 12. D. HCFC 22. |

D. HCFC 22.

Correct. HCFC may be used as a trace gas when mixed with nitrogen for pressure testing, then vented into the atmosphere as it is not being used as a refrigerant. |

A. helium.

Incorrect. Helium would not be detected by leak dectecors. B. oxygen. Incorrect. Oxygen should never be added to a system. Oxygen causes corrosion and can cause explosions when in contact with oil under pressure. C. CFC 12. Incorrect. CFC 12 is not allowed as a trace gase. |

|

|

58. When charging a system, the refrigerant cylinder pressure may drop too low for further charging. Which of the following methods should not be used to increase the pressure?

A. Heat the cylinder with a torch. B. Heat the cylinder with a heat lamp. C. Heat the cylinder by immersing it in a tub of warm water. D. Heat the cylinder by wrapping it in a specially built electric heater. |

A. Heat the cylinder with a torch.

Correct. You should never heat a cylinder with a torch, and should never raise the temperature above 125°F. |

B. Heat the cylinder with a heat lamp.

Incorrect. Using a heat lamp is an acceptable method for heating a cylinder. Care should be taken never to raise the temperature above 125°F. C. Heat the cylinder by immersing it in a tub of warm water. Incorrect. Immersing a refrigerant cylinder in a tub of warm water (80°F to 110°F) is an acceptable method to use for heating a cylinder. Care should be taken never to raise the temperature above 125°F. D. Heat the cylinder by wrapping it in a specially built electric heater. Incorrect. Using a specially built electric heater is an acceptable method for heating a cylinder. Care should be taken never to raise the temperature above 125°F. |

|

|

59. A term used to rate vacuum pumps is used to describe the pump's ability to draw a vacuum. Essentially, the pump must create a vacuum within itself that is lower than in the system, so that gases will flow from the system to the pump. The point at which a pump can no longer create a

pressure difference is called A. dead head pressure. B. blank-off pressure. C. blocked tight static pressure. D. point of no pressure difference. |

B. blank-off pressure.

Correct. |

A. dead head pressure.

Incorrect. The term dead head (or shut-off head) refers to blocking off a centrifugal pump to read the pressure differential across it. C. blocked tight static pressure. Incorrect. Blocked tight static pressure refers to the pressure developed by a fan when the outlet is blocked off. D. point of no pressure difference. Incorrect. The point of no pressure difference refers to the point on a hydronic system where the pressure tank is connected to the system. |

|

|

60. Vacuum pump oil is a special oil because

A. it won't absorb water. B. it has a low vapor pressure to ensure that it won't vaporize at low pressures. C. it rarely needs changing. D. it is non-toxic and can be disposed of easily. |

B. it has a low vapor pressure to ensure that it won't vaporize at low pressures.

Correct. Note that the UA text Refrigeration on page 488 incorrectly states that vacuum pump oil has a high vapor pressure. This would cause it to easily evaporate at even high temperatures. As an example, gasoline has a higher vapor pressure than water, and evaporates more quickly. |

A. it won't absorb water.

Incorrect. In fact, vacuum pump oil will absorb water, which is why it is so important to change the oil before each evacuation to ensure that no water is entrained in it. C. it rarely needs changing. Incorrect. Vacuum pump oil should be changed frequently since it absorbs water and other contaminants. D. it is non-toxic and can be disposed of easily. Incorrect. In fact, used vacuum pump oil is considered a toxic waste and must be disposed of accordingly. |

|

|

61. Which of the following methods will not decrease the time needed to evacuate a large refrigeration system?

A. Using large diameter fittings. B. Keeping hose lengths as short as possible. C. Triple evacuation. D. Using multiple vacuum pumps. |

C. Triple evacuation.

Correct. Triple evacuation is a method that is no longer recommended since it vented refrigerant into the atmosphere. Further, it did not reduce evacuation time at all, but was a method used to dilute any contaminants within the system as much as possible. |

A. Using large diameter fittings.

Incorrect. The use of large diameter fittings is recommended to speed up the process. B. Keeping hose lengths as short as possible. Incorrect. Using short hoses is recommended to speed up the process. D. Using multiple vacuum pumps. Incorrect. The use of multiple pumps of moderate capacity is recommended over using One large capacity pump for evacuating large systems such as a water chiller. |

|

|

62. A danger with leaving a vacuum pump running all night is

A. pulling more than 30 in.Hg. vacuum. B. exceeding the pumps running time capabilities. C. pump oil could be lost during a power outage. D. Both B and C from above. |

D. Both B and C from above.

Correct. B. exceeding the pumps running time capabilities. Partially correct. The pump manufacturer's instructions should be consulted to ensure that the pump can safely run that long. C. pump oil could be lost during a power outage. Partially correct. Once a vacuum has been pulled on the system, it becomes a large volume of low pressure, and can pull the oil from the vacuum pump if the pump is shut off and not isolated from the syetm. |

A. pulling more than 30 in.Hg. vacuum.

Incorrect. It is impossible to pull a vacuum below 30 in.Hg. since no pressure exists at 30 in.Hg. |

|

|

63. Vacuum pump oil that is fresh

A. has a smooth milky appearance. B. has a clear appearance. C. has a somewhat cloudy appearance. D. is very thick and heavy. |

B. has a clear appearance.

Correct. New oil has a clean and clear appearance. If it looks otherwise, it should be changed. |

A. has a smooth milky appearance.

Incorrect, This is an indication that the oil has moisture in it. C. has a somewhat cloudy appearance. Incorrect. This is an indication that the oil has moisture in it. D. is very thick and heavy. Incorrect. Vacuum pump oil is light. |

|

|

64. A refillable refrigerant cylinder must not be filled above _____ percent of its capacity by weight.

A. 100% B. 90% C. 80% D. 70% |

C. 80%

Correct |

|

|

|

65. A refrigerant with the ANSI/ASHRAE Standard 34-1992 safety classification of A1 has

A. high toxicity and high flammability. B. low toxicity and no flame propagation. C. low toxicity and high flammability. D. high toxicity and no flame propagation. |

B. low toxicity and no flame propagation.

Correct. |

A. high toxicity and high flammability.

Incorrect. A means lower toxicity, B means higher toxicity. 1 means no flame propagation while 3 means higher flammability. C. low toxicity and high flammability. Incorrect. A means lower toxicity, B means higher toxicity. 1 means no flame propagation while 3 means higher flammability. D. high toxicity and no flame propagation. Incorrect. A means lower toxicity, B means higher toxicity. 1 means no flame propagation while 3 means higher flammability. |

|

|

66. All appliances containing more than 50 lbs. of refrigerant (except commercial and industrial

Process refrigeration) must be repaired when the annual leak rate exceeds A. 5% B. 15% C. 25% D. 35% |

B. 15%

Correct. EPA requires that all appliances containing more than 50 lbs. of refrigerant (Except commercial and industrial process refrigeration) must be repaired when the annual leak rate exceeds 15%, and commercial and industrial process refrigeration must Be repaired when the annual leak rate exceeds 35%. |

|

|

|

67. When charging a chilled water system, charging is usually done as a liquid. However, if the machine is in a deep vacuum, the initial charge should be as a vapor. Why?

A. Charging as a vapor is faster for chillers because the system is in a deep vacuum. B. Charging as a vapor allows system pressure to stabilize and prevents thermal shock to the system. C. Charging as a vapor until the system reaches ambient temperature prevents condensation inside the system. D. Charging as a vapor until the system temperature has risen above 32°F prevents freezing of water in the tubes. |

D. Charging as a vapor until the system temperature has risen above 32°F prevents

freezing of water in the tubes. Correct. The system must be charged as a vapor until the system pressure has reached a pressure corresponding to a temperature higher than 32°F. |

A. Charging as a vapor is faster for chillers because the system is in a deep vacuum.

Incorrect. Vapor charging takes longer for all types of systems. The real danger when charging a system is damage to the tubes from water freezing and bursting the tubes. This is what needs to be prevented. B. Charging as a vapor allows system pressure to stabilize and prevents thermal shock to the system. Incorrect. The real danger when charging a system is damage to the tubes from water freezing and bursting the tubes. This is what needs to be prevented. C. Charging as a vapor until the system reaches ambient temperature prevents condensation inside the system. Incorrect. No moisture exists in the system, so condensation cannot form. The real danger when charging a system is damage to the tubes from water freezing and bursting the tubes. This is what needs to be prevented. |

|

|

68. When charging a system, several methods are available for checking the refrigerant charge. In order to charge by monitoring the subcooling, one must

A. monitor discharge temperature and liquid line temperature close to the metering device and charge until the liquid line temperature falls below the discharge temperature by the expected amount of subcooling. B. monitor discharge temperature and liquid line temperature close to the metering device and charge until the discharge temperature falls below the liquid line temperature by the expected amount of subcooling. C. monitor saturated suction temperature and suction gas temperature and charge until saturated suction temperature falls below the suction gas temperature by the expected amount of subcooling. D. monitor saturated suction temperature and suction gas temperature and charge until suction gas temperature falls below the saturated suction temperature by the expected amount of subcooling. |

A. monitor discharge temperature and liquid line temperature close to the metering device and charge until the liquid line temperature falls below the discharge temperature by the

expected amount of subcooling. Correct. |

B. monitor discharge temperature and liquid line temperature close to the metering device and charge until the discharge temperature falls below the liquid line temperature by the

expected amount of subcooling. Incorrect. Subcooling occurs when the liquid line temperature falls below discharge temperature. C. monitor saturated suction temperature and suction gas temperature and charge until saturated suction temperature falls below the suction gas temperature by the expected amount of subcooling. Incorrect. This is a method for checking superheat, not subcooling. D. monitor saturated suction temperature and suction gas temperature and charge until suction gas temperature falls below the saturated suction temperature by the expected amount of subcooling. Incorrect. This is a method for checking superheat. Further, suction gas temperature cannot be lower than saturated suction temperature. It will either be equal or higher. |

|

|

69. Insufficient refrigerant will cause

A. excessive head pressure. B. low suction pressure and insufficient cooling. C. low suction pressure and over cooling. D. high discharge temperature. |

B. low suction pressure and insufficient cooling.

Correct. |

A. excessive head pressure.

Incorrect. Excessive head pressure is a symptom of too much charge. C. low suction pressure and over cooling. Incorrect. Suction pressure will be low, but cooling capacity will also be low. D. high discharge temperature. Incorrect. High discharge temperature is a symptom of too much charge. |

|

|

70. Most compressors are positive displacement machines. Name a compressor that is not a positive

displacement machine. A. Reciprocating. B. Helical-rotary (screw) C. Rotary. D. Centrifugal. |

D. Centrifugal.

Correct. |

A. Reciprocating.

Incorrect. The reciprocating compressor is of the positive displacement type. B. Helical-rotary (screw) Incorrect. The helical-ratary (screw) compressor is of the positive displacement type. C. Rotary. Incorrect. The rotary compressor is of the positive displacement type. |

|

|

71. The ratio of the actual volume of refrigerant vapor pumped to the theoretical displacement volume is known as

A. volumetric efficiency. B. volumetric ratio. C. compression efficiency. D. compression ratio. |

A. volumetric efficiency.

Correct. |

B. volumetric ratio.

Incorrect. There is no term known as volumetric ratio. C. compression efficiency. Incorrect. There is no term known as compression efficiency. D. compression ratio. Incorrect. Compression Ratio = Discharge pressure, psia. Divided by Suction pressure, psia. |

|

|

72. A compressor in which the compressor and motor are both sealed within the same pressurized housing is known as a

A. sealed compressor. B. pressurized compressor. C. hermetic compressor. D. hermetic compressor. |

C. hermetic compressor.

Correct. |

A. sealed compressor.

Incorrect. There is no term known as a sealed compressor. B. pressurized compressor. Incorrect. There is no term know as a pressurized compressor. D. hermetic compressor. Incorrect. There is no term know as a hermenet compressor. |

|

|

73. The passage of liquid refrigerant through the compressor suction and discharge valves should be

avoided and is known as A. choking the compressor. B. slugging the compressor. C. kicking the compressor. D. shocking the compressor. |

B. slugging the compressor.

Correct. |

A. choking the compressor.

C. kicking the compressor. D. shocking the compressor. Incorrect. |

|

|

74. Modern high-speed reciprocating compressors typically operate at

A. 1750 rpm. B. 3450 rpm. C. 5250 rpm. D. Both A and B from above. |

D. Both A and B from above.

Correct. Modern high-speed reciprocating compressors typically operate at 1750 rpm and 3450 rpm. A. 1750 rpm. Partially correct. There is another common speed also. B. 3450 rpm. Partially correct. There is another common speed also. |

C. 5250 rpm.

Incorrect. |

|

|

75. Compressor capacity decreases as

A. discharge pressure increases. B. suction pressure decreases. C. compressor speed decreases. D. All of the above. |

D. All of the above.

Correct. A. discharge pressure increases. B. suction pressure decreases. C. compressor speed decreases. |

|

|

|

76. An advantage of the scroll compressor is

A. smooth, quiet operation. B. low torque variation through overlapping compression cycles. C. few moving parts. D. All of the above. |

D. All of the above.

Correct. |

|

|

|

77. How can you identify reverse operation with a scroll compressor?

A. The compressor will not compress. B. The compressor will stop on motor overload. C. You can see it running backwards. D. Both A and B from above. |

D. Both A and B from above.

Correct. A. The compressor will not compress. B. The compressor will stop on motor overload. |

|

|

|

78. During scroll compression,

A. refrigerant vapor enters from the outside of the scroll and exits at the center. B. refrigerant vapor enters from the center of the scroll and exits at the outside. C. refrigerant vapor enters from one side of the scroll and exits from the other side. D. Both A and C from above. |

A. refrigerant vapor enters from the outside of the scroll and exits at the center.

Correct. |

B. refrigerant vapor enters from the center of the scroll and exits at the outside.

C. refrigerant vapor enters from one side of the scroll and exits from the other side. D. Both A and C from above. Incorrect. Refer to page 94 of Refrigeration for an explanation of scroll operation. |

|

|

79. Capacity control on a helical-rotary (screw) compressor is obtained using

A. inlet vanes. B. hot gas bypass. C. variable speed motors. D. a sliding valve. |

D. a sliding valve.

Correct. |

A. inlet vanes.

Incorrect. Inlet vanes are used for capacity control on a centrifugal compressor. B. hot gas bypass. Incorrect. Hot gas bypass is used for reciprocating compressors. C. variable speed motors. Incorrect. Screw compressors are intended to operate at constant speed. |

|

|

80. The screw-type mechanism used in helical-rotary compressors are known as

A. rotors. B. scrolls. C. a helix. D. vanes. |

A. rotors.

Correct. |

B. scrolls.

Incorrect. Scrolls are used in scroll compressors, which operate using a different principle. C. a helix. Incorrect. The screws are not known by this name. D. vanes. Incorrect. Vanes are terms used with rotary vane compressors. |

|

|

81. The component in a centrifugal compressor that actually does the compressing is known as

A. an impeller. B. a rotor. C. a centrifuge. D. a centripetal. |

A. an impeller.

Correct. |

B. a rotor.

Incorrect. Rotors are used in helical-rotary compressors and rotary compressors. C. a centrifuge. Incorrect. A centrifuge is an apparatus that rotates at high speed and separates substances of different densities. D. a centripetal. Incorrect. Centripetal is actually an adjective and is used to describe the force acted upon a body moving along a curved path, that is directed toward the center of the curved path (opposed to centrifugal). |

|

|

82. A centrifugal compressor controls capacity through the use of

A. variable speed. B. on-off control. C. vortex dampers. D. Both A and C from above. |

D. Both A and C from above.

Correct. A. variable speed. Partially correct. There is another common method for controlling capacity. C. vortex dampers. Partially correct. There is another method for controlling capacity in addition to vortex dampers (also called inlet guide vane dampers or pre-rotation vanes). |

B. on-off control.

Incorrect. On-off control is not acceptable for centrifugals because of the high current draw and excessive motor heat created at startup. |

|

|

83. Bearings in a centrifugal compressor can be checked by

A. sliding the impellor back and forth to check for slop. B. trying to move the shaft at right angles to the bearing. C. checking the temperature of the oil returning from the bearing. D. manually spinning the impellor while listening for grinding noises. |

C. checking the temperature of the oil returning from the bearing.

Correct. A high temperature in the oil indicates a bearing with a large amount of friction, indicating that a problem exist. |

A. sliding the impellor back and forth to check for slop.

Incorrect. B. trying to move the shaft at right angles to the bearing. Incorrect. D. manually spinning the impellor while listening for grinding noises. Incorrect. It is not easy to get to the impellor to make such a check, and is cost prohibitive. It is also unlikely that anything could be heard in a noisy mechanical room. |

|

|

84. A small access valve which is similar to the air valve used on tires is known as a

A. Schriber valve. B. Schrader valve. C. Schreuder valve. D. Schroder valve. |

B. Schrader valve.

Correct. |

A. Schriber valve.

C. Schreuder valve. D. Schroder valve. Incorrect. |

|

|

85. A valve used to prevent flow of liquid refrigerant to the evaporator and to avoid flood back to the compressor during off cycles is the

A. check valve. B. bypass valve. C. relief valve. D. solenoid valve. |

D. solenoid valve.

Correct. Solenoid valves have many applications in refrigeration systems, the principle one being to prevent flow of liquid refrigerant to the eveporator and to avoid flood back to the compressor during off cycles. |

A. check valve.

Incorrect. Check valves prevent flow in the wrong direction. B. bypass valve. Incorrect. The bypass valve is used for capacity control with reciprocating compressors. C. relief valve. Incorrect. A relief valve is a safety device designed to prevent pressure from exceeding a safe level. |

|

|

86. A special valve used to prevent evaporator temperature from falling below a predetermined

minimum pressure regardless of suction pressure is the A. evaporator pressure regulator. B. pressure reducing valve. C. suction pressure regulator. D. None of the above. |

A. evaporator pressure regulator.

Correct. An example of an application for this valve is on systems with multiple evaporators operating at different temperatures. |

B. pressure reducing valve.

Incorrect. Pressure reducing valves are commonly used on compressed air systems, but not to prevent low pressure in an evaporator. C. suction pressure regulator. Incorrect. Although it sounds like this valve would be used to control pressure in the evaporator, its purpose is actually to limit the suction pressure at the compressor to a maximum value. D. None of the above. Incorrect. |

|

|

87. A metering device with the characteristic of feeding liquid into the evaporator at the same rate at which the liquid flows from the condenser is the

A. thermostatic expansion valve. B. high-side float valve. C. low-side float valve. D. constant pressure expansion valve. |

B. high-side float valve.

Correct. This valve consists of a float and a needle valve, which creates the pressure drop separating the high-side from the low-side of the system. As the liquid level from the condenser raises, the float rises and opens the needle valve, forcing refrigerant into the evaporator. As the liquid level from the dondenser drops, the float drops also and closes the needle valve, restricting the flow to the evaporator. |

A. thermostatic expansion valve.

Incorrect. The TEV meters refrigerant based on the suction line temperature and maintains a constant superheat. C. low-side float valve. Incorrect. The low-side float valve functions to maintain a constant level of liquid refrigerant in a flooded evaporator. D. constant pressure expansion valve. Incorrect. The constant pressure expansion valve functions to maintain a constant pressure in the evaporator, which serves to maintain a constant suction pressure and load on the compressor. |

|

|

88. In a thermostatic expansion valve, three forces act on the diaphragm in the power head, which is connected to the valve. Evaporator pressure acts to ________ the valve, spring pressure acts to _______ the valve and suction pressure from the bulb attached to the evaporator outlet acts to

_______.the valve. A. open; open; close. B. close; close; open. C. close; open; open. D. open; close; close. |

B. close; close; open.

Correct. Both the evaporator pressure and the spring pressure act to close the valve, while the suction pressure from the bulb acts to open the valve. |

A. open; open; close.

Incorrect. It is true that the force of the suction pressure from the bulb opposes the other two pressures, but not in the manner described by this choice. C. close; open; open. Incorrect. The pressure from the evaporator and the spring act in the same direction and oppose the force of the suction pressure from the bulb. D. open; close; close. Incorrect. The pressure from the evaporator and the spring act in the same direction and oppose the force of the suction pressure from the bulb. |

|

|

89. The metering device that actually measures temperature rather than pressure or liquid levels is the

A. temperature activated expansion valve. B. thermostatic temperature valve. C. capillary tube. D. thermal electric valve. |

D. thermal electric valve.

Correct.` |

A. temperature activated expansion valve.

Incorrect. There is no valve known by this name. B. thermostatic temperature valve. Incorrect. There is no valve known by this name. C. capillary tube. Incorrect. The capillary tube actually meters refrigerant by restricting the flow through the small inner diameter of the tube. |

|

|

90. Suction line filter-driers should be installed whenever

A. a system is serviced. B. a leak has occurred. C. a hermetic compressor motor burnout has occurred. D. a thermostatic expansion valve has been replaced. |

C. a hermetic compressor motor burnout has occurred.

Correct. Suction line filter-driers should be installed whenever a hermetic compressor motor burnout has occurred to fiter out debris and carbon char and to neutralize system acid, which is usually generated. |

A. a system is serviced.

Incorrect. It is only necessary to install a suction line filter-drier when something has occurred that would contaminte the system. B. a leak has occurred. Incorrect. After the leak has been repaired, the liquid line filter-drier will be sufficient to pick up any remaining moisture left in the system. D. a thermostatic expansion valve has been replaced. Incorrect. There is not need to install a suction line filter-drier when replacing a TXV. |

|

|

91. Filter-driers and driers are filled with a material that is able to catch and retain moisture and acid.

This material is called A. water dry. B. desiccant. C. dry-out. D. moisture dry. |

B. desiccant.

Correct. |

A. water dry.

C. dry-out. D. moisture dry. Incorrect. |

|

|

92. Suction line filter-driers are usually equipped with gage connections so that pressure drops can be determined. Why?

A. So that accurate superheat calculations can be made. B. To ensure that excessive load is not imposed on the compressor. C. To ensure that flash gas does not occur in the filter-drier. D. So that you can determine when to change the filter-drier. |

D. So that you can determine when to change the filter-drier.

Correct. Manufacturers publish tables that specify permissible core pressure drops. When the drop exceeds recommendations the core should be replaced. |

A. So that accurate superheat calculations can be made.

Incorrect. While it is true that a pressure drop through a suction line filter-drier will affect superheat calculations, the differernce is slight and of little consequence. B. To ensure that excessive load is not imposed on the compressor. Incorrect. Suction line filter-driers are designed with low pressure drops so as not to affect the system. C. To ensure that flash gas does not occur in the filter-drier. Incorrect. The refrigerant is already in a vapor state in the suction line, so flash gas cannot occur and is of no concern. |

|

|

93. In general, the greater the number of rows in an evaporator

A. the more closely the leaving air temperature will be to that of the refrigerant. B. the more dehumidification can take place. C. the colder the leaving air will be. D. All of the above. |

D. All of the above.

Correct. A. the more closely the leaving air temperature will be to that of the refrigerant. Partially correct. B. the more dehumidification can take place. Partially correct. C. the colder the leaving air will be. Partially correct. Other factors exist with greater number of rows. |

|

|

|

94. Increasing air flow over an evaporator

A. increases evaporator capacity. B. decreases evaporator capacity. C. does not affect evaporator capacity. D. None of the above. |

A. increases evaporator capacity.

Correct. The more air that flows past an evaporator, the more energy is absorbed by the refrigerant. Using the formula for sensible heat transfer (below), it can be seen that if the temperature difference between the air and the refrigerant remains the same, an increase in air flow (cfm) will result in an increase of energy transfer (btuh). Btuh = cfm×1.08× ΔT |

B. decreases evaporator capacity.

Incorrect. C. does not affect evaporator capacity. Incorrect. The more air that flows past an evaporator, the more energy is absorbed by the refrigerant. Using the formula for sensible heat transfer (below), it can be seen that if the temperature difference between the air and the refrigerant remains the same, an increase in air flow (cfm) will result in an increase of energy transfer (btuh). Btuh = cfm×1.08× ΔT D. None of the above. Incorrect. |

|

|