![]()

![]()

![]()

Use LEFT and RIGHT arrow keys to navigate between flashcards;

Use UP and DOWN arrow keys to flip the card;

H to show hint;

A reads text to speech;

70 Cards in this Set

- Front

- Back

|

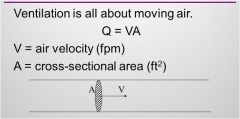

Air Flow

Q = VA |

Q = VA

V = air velocity (fpm) A = cross-sectional area (ft2) Q = air flow (cfm) |

|

|

2 types of energy

Potential Kinetic |

Potential: stored energy

Kinetic: moving energy |

|

|

Energy in ventilation is?

|

pressure

|

|

|

Kinetic energy is ?

Potential energy is ? |

Kinetic energy is velocity pressure.

Potential energy is static pressure. |

|

|

Velocity Pressure

The force applied by moving air hitting a surface. Velocity pressure is always? |

Velocity pressure is always positive.

|

|

|

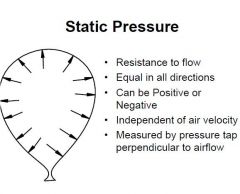

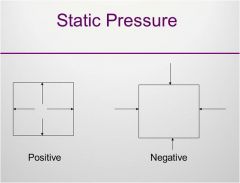

Static Pressure.

The force exerted by air molecules striking the surface of a container. Static pressure is the same in all directions. In ventilation, we are concerned with the relative static pressure. What is the static pressure inside the duct relative to the atmosphere outside of the duct? |

Positive inside duct

Negative outside |

|

|

What causes air to move?

|

Change in static pressure causes air to move.

|

|

|

Air moves from ?

|

high static pressure to low static pressure.

|

|

|

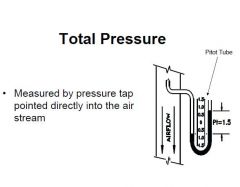

Total Pressure

Total pressure is the sum of static pressure and velocity pressure |

TP = ST + VP

|

|

|

Velocity and VP

Velocity is directly proportional to the square root of velocity pressure |

V = 4005√VP

V= velocity (fpm) VP= velocity pressure (in of H20) |

|

|

Energy losses are directly proportional to ?

|

Energy losses are directly proportional to velocity pressure (VP).

Energy loss = K * VP |

|

|

Friction losses

Friction losses in the duct are directly proportional to ? |

Friction losses in the duct are directly proportional to velocity pressure (VP)

Loss = Fh * VP Fh = loss coefficient VP = velocity pressure in duct (in H20) |

|

|

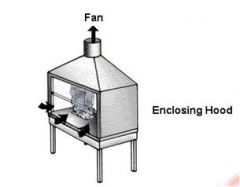

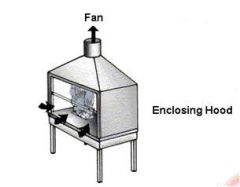

What is a hood?

|

The hood is a capture device - it collects, recieve, and/or contains the contaminants that need to be controlled.

Examples: Enclosing: lab fume hood Receiving: canopy hood Capturing: welding bench hood |

|

|

2 hood categories?

|

external hood

enclosing hood |

|

|

External Hoods

name 4 types |

Duct opening

Slot hood Compound hoods Recieving hoods - Canopy hood, abrasive grinding wheel. |

|

|

Recieving hoods take advantage of contaminant momentum.

Canopy hoods should only be used for? |

“Catch” contaminants moving with some velocity from the process towards the hood, e.g., a canopy hood over a heated degreaser

Canopy hoods should only be used for hot processes with minimal cross drafts. |

|

|

Enclosing hoods

examples? |

-Lab hood

-Glove box -Paint booth |

|

|

Hood design criteria

|

-Cross drafts

-Capture velocity: toxicity, particulate or vapor, contaminant inertia -Work position -Hood efficiency |

|

|

Best hood design?

|

-Start with enclosing the process entirely.

-Remove only the sides to allow process to work |

|

|

Air consist of many different gases and vapors but predominantly?

|

•nitrogen (78%)

•oxygen (20.9%) •water vapor (usually 1-2%) •argon (about 1%) •carbon dioxide (around 0.3%). |

|

|

1% = ? ppm

|

1% = 10,000ppm

|

|

|

Static pressure characteristics

|

Static pressure is:

felt in all directions within a duct. Created by gravity and modified by the fan. Negative pressure (i.e., pressure inside the duct is lower than outside) tends to collapse the duct, whereas positive pressure tends to blow it up. |

|

|

Total pressure is the sum of?

|

SP + VP = VP

|

|

|

The velocity pressure of moving air is related to ?

|

Force.

Gas molecules have mass and velocity and therefore possess momentum. If you imagine these gas molecules hitting a plate that is in their way, they would hit with a certain force per unit area. This is velocity pressure (VP). |

|

|

From an IH standpoint, what is the most important part of the ventilation system?

|

The hood is the most important and should govern the design and choice of all other system components.

|

|

|

Hoods are characterized by what four factors?

|

•Hood static pressure

•Hood entry loss •Face velocity •Capture velocity |

|

|

Hood static pressure describes what?

|

Hood static pressure describes the operating static pressure in the duct 2 to 6 duct diameters downstream of the hood. It is negative and is responsible for moving the air.

|

|

|

Hood Entry Loss and Coefficient of Entry

|

Hood entry loss describes how efficiently the hood converts hood static pressure into air movement.

At the hood, all static pressure is converted into velocity pressure and hood entry losses. The smaller the hood entry loss, the more efficient the hood. Expressed the relationship in the equation: Hood Entry Loss / SPh / = VP + he Where: / SPh / = the absolute value of the hood static pressure 2 to 6 duct diameters downstream from the hood VP = duct velocity pressure at the same point he = hood entry loss |

|

|

Face Velocity

|

If air moves through a large area such as the opening of a laboratory fume hood, we can measure and calculate the average face velocity across this area. In ventilation terms, this is called the face velocity of the hood.

|

|

|

Air cleaners are characterized by what three factors ?

|

•Pollutants removed by the air cleaner

•Pressure drop across the air cleaner •Filter efficiency |

|

|

What shape of duct is best for contaminant control?

|

Round duct is better than rectangular duct for contaminant control.

|

|

|

Elbows and other disturbances to airflow should be located at least ___ duct diameters away from the fan inlet or outlet.

|

5 duct diameters away from the fan inlet or outlet.

|

|

|

Fan Law 1: Changes in volume flow (cfm) vary directly with changes in fan speed.

|

Q1 / Q2 = n1 / n2

Where: n = revolutions per minute Q = volume flow rate SP = static pressure P = power |

|

|

Fan Law 2: Changes in static pressure vary directly with the square of changes in fan speed.

|

SP1 / SP2 = ( n1 / n2 )2

Where: n = revolutions per minute Q = volume flow rate SP = static pressure P = power |

|

|

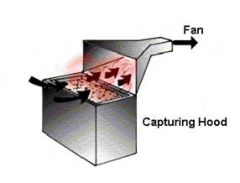

Capturing hood

|

“Reach out” to capture contaminants generated outside the hood, e.g., a welding bench with a slot exhaust across the back of the table.

|

|

|

Fan Law 3. Changes in brake horsepower vary directly with the cube of changes in fan speed

|

P1 / P2 = ( n1 / n2 )3

Where: n = revolutions per minute Q = volume flow rate SP = static pressure P = power |

|

|

The OEL is generally _% of the LFL?

|

The OEL is generally 1% (or less) of the LFL. Therefore, airborne concentrations of flammable or combustible materials in occupied work areas should be controlled below the OEL in order to protect workers’ health

|

|

|

What type of hoods generally use less air volume than open hoods?

|

Enclosing hoods

|

|

|

Capture velocity of air decreases exponentially with ?

|

Capture velocity of air decreases exponentially with increased distance from the hood

|

|

|

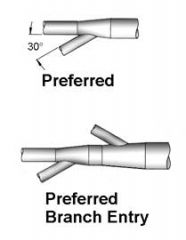

All branches should enter the main duct at an angle of less than __° in a tapered transition.

|

All branches should enter at a gradual expansion and at an agnle of 30° or less (preferrred).

To minimize turbulence, the branches should be connected in the taper or at the top of the main duct, with no two branches entering at opposite sides |

|

|

Capture Velocity

|

The minimum hood-induced air velocity necessary to capture and convey the contaminant into the hood.

|

|

|

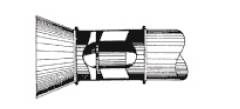

Velocity duct measurements need to be an average of the velocities of a cross section of duct.

Probe placement- Ideal location is ? Non-ideal location? |

Ideal location is ≥ 7 duct diameters downstream from elbows, duct entries or other obstruction.

Under non-ideal location, use 2 perpendicular duct transverses. |

|

|

Choose diultion ventilation control only if these conditions are met. (6)

|

1. No workers exposed to excessive concentration.

2. LEVis not feasible or appropriate. 3. Contaminant is not highly toxic. 4. Contaminant is easly transported to exhaust point. 5. Costs of supply air are not excessive 6. Existing ventilation rates are relatively low. |

|

|

The following should be considered when designing a dilution ventilation system.

|

-Locate exhaust opening near contaminant source.

-Workers should be positioned between supply and contaminant. -Replace exhaust air -Outside contaminants should be considereed when placeing location of air intakes. Consider mixing effects of room configuration. |

|

|

The mixing factor is used to estimate an airflow necessary to remove contaminants in a room with less than ideal mixing.

|

Q' = effective air flow (cfm)

Q = actual air flow (cfm) K = mixing factor (dimensionless) Q'=Q/K |

|

|

Two general fan categories.

Axial: fan axis is _ to air flow. Centrifugal: fan axis is _ to air flow. |

Axial: fan axis is parallel to air flow.

Centrifugal: fan axis is perpendicular to air flow. |

|

|

Category: Axial fans

Propellar fans Performance is very _. A large change in airflow with _ change in SP. works against " ? examples? |

Performance is very sensitive.

Large change in airflow with small changes in SP> Works against low pressure drops <1" H20. Window and attic fans. |

|

Category: Axial fans

Tube axial fans works against? examples? |

Works against medium pressure drops <2"

Narrow propeller blades in a duct. |

|

|

Vane axial fans

similar to tubeaxial, but ? works against higher pressure up to _" |

Similar to tubeaxial, but improved efficiency by directing and straightening the flow. As a results they have higher SP with less dependence on duct SP.

Works against high pressures up to 8" Propeeler in duct with straightening vanes on discharge. |

|

|

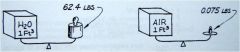

Air density

Air has a weight density of _lbs/ft3 or _kgs/m3 at STP. |

Air has a weight density of 0.075lbs/ft3 or 1.2kgs/m3 at STP.

Water is 830 times that of air, 62.4lbs/ft3 or 1000kgs/m3 |

|

|

Specific gravity

The ratio of? |

The ratio of the mass of a gas or vapor to the mass of an equal volume of air.

Ex. Carbon monoxide has a specific gravity of 0.968. which means that CO weights 96.8% of the the weight of air. |

|

|

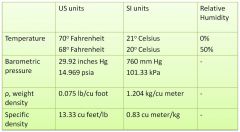

STP

temperature pressure density specific density |

STP

|

|

|

Density correction

At STP, d=? At higher temperature and altitude, d =? At lower temperature and altitudes, below sea level, d =? |

At STP, d=1

At higher temperature and altitude, d < 1 At lower temperature and altitudes, below sea level, d >1 |

|

|

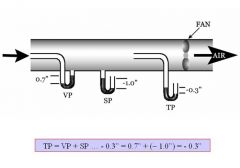

SP, TP, VP

If the end of the manometer is inserted facing directly into the air stream, the manometer will not only measure SP, but will also measure? |

The influence of the air impacting on the end of the probe, this TP.

VP can be estimated by subtracting the SP from TP. |

|

|

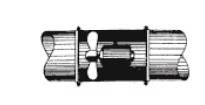

Pitot tube is often used to measure?

The tip of the pitot tube faces into the airstream and measure? Eight small holes aligned along the outside tube measure ? |

measure TP and SP.

pitot tube faces into the airstream and measures TP. Eight small holes aligned along the outside tube measure SP |

|

|

Thermal Anemometer

Aka Measures? |

Aka Hot Wire Anemometer

Most commonly used. Measures air velocity by comparing ambient temperature to the heat loss from a heated lement caused by moving air. Do not use in ducts with flammable vapor/gases. |

|

|

Swinging Vane Anemometer

measures? |

Measures static pressure and air velocity

|

|

|

Rotating Vane Anemometer

measures? not used for? |

An accurate instrument for measuring air flow rate at large supply and exhaust openings.

Not used for making hood velocity measurements. RVA is not suitable for in-duct measurements or for use with openings less than 20 inches. |

|

|

Manometer

|

A device that measures pressure differences.

Usually U-shaped glass tube containing water or oil. Also available as a digital type |

|

|

Pitot tube

used to measure? |

A device used to take more accurate measurements of total anv velocity pressure in an air stream of a duct.

Used in conjunction with a manometer can measure Hood Static Pressure (SPh) Measures SP, VP, TP |

|

|

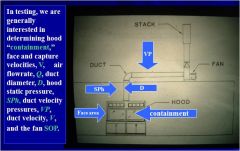

Placements for ventilation testing

|

see picture

|

|

|

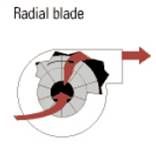

Fan Category: Centrifugal

Radial impeller describe blades. Used for what type of loads? Ideal for ? |

Straight blades

Used for heavy loads No material build up Ideal for transporting dusts and particulate matter. |

|

|

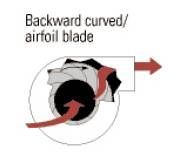

Fan Category: Centrifugal

Backward Curved Blades Advantages? Blade shape? conducive for what? |

High efficiency

Non-overloading characteristics (won't burn itself up if there is no static pressure to work against). Bade shaped conducive to material build up. Quiest operation |

|

|

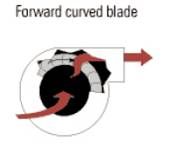

Fan Category: Centrifugal

Forward Curve Aka? Use for? Disadvantages? |

"Squirrel cage"

Low to moderate static pressure. Potential material build up problems. Used in HVAC and dilution ventilation (moving large volumes of air against low pressure). |

|

|

How are fans rated?

|

Fans are rated by the fan static pressure and air flow.

|

|

|

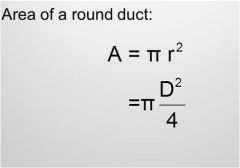

Area of a round duct?

|

|

|

|

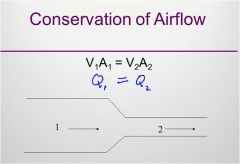

Conservation of airflow?

|

|

|

|

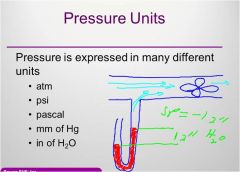

Pressure can be expressed in many different units such as?

|

|

|

|

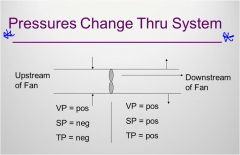

Pressure changes through system.

VP, SP and TP upstream of fan? |

|

|

|

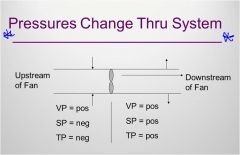

Pressure changes through system.

VP, SP and TP down stream of fan? |

|